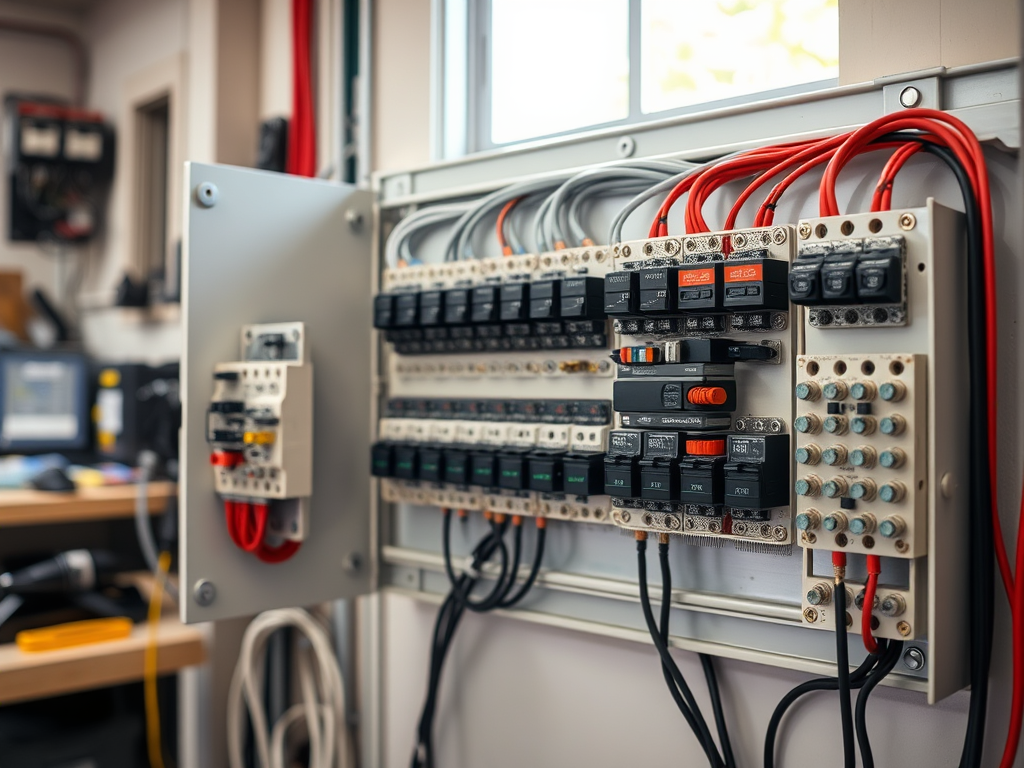

How to Building Custom Electrical Panel

Building a custom electrical panel is a practical and valuable skill used in industrial automation, commercial buildings, workshops, and specialized machinery. A properly designed panel improves safety, reliability, and long-term maintainability. This guide walks through the full process of planning, building, wiring, and commissioning a custom electrical panel, even if you are starting from scratch….