Building a custom electrical panel is a practical and valuable skill used in industrial automation, commercial buildings, workshops, and specialized machinery. A properly designed panel improves safety, reliability, and long-term maintainability. This guide walks through the full process of planning, building, wiring, and commissioning a custom electrical panel, even if you are starting from scratch.

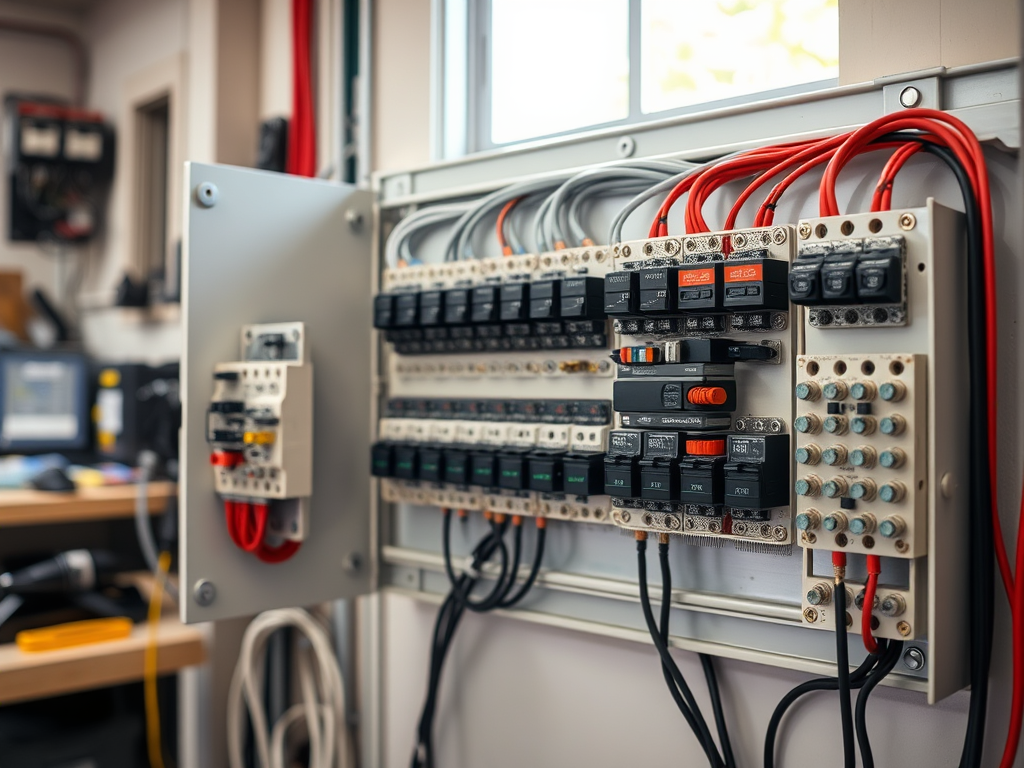

[Image: Example of a finished custom electrical control panel]

STEP 1: DEFINE THE PANEL PURPOSE

Every electrical panel begins with a clear purpose. Before selecting components or drilling an enclosure, determine what the panel must do. Identify the voltage requirements, whether the system is single-phase or three-phase, and the type of loads being controlled. Loads may include motors, heaters, lighting circuits, PLCs, sensors, or variable frequency drives.

You should also consider where the panel will be installed. Indoor panels face fewer environmental challenges than outdoor or wash-down environments. Planning for future expansion at this stage can save significant cost later by allowing space for additional breakers or control components.

STEP 2: CREATE A PANEL LAYOUT AND SCHEMATIC

A clean panel layout separates professional work from amateur builds. Start by drawing a wiring schematic that shows power flow, control logic, safety devices, and grounding. Next, sketch a physical layout of the enclosure.

Power components such as disconnects and breakers are usually grouped together. Control components like relays, PLCs, and power supplies should be separated from high-voltage wiring. Leave space for wire duct, airflow, and labeling. Many builders use CAD software, but even a detailed hand sketch is effective.

[Image: Electrical panel wiring schematic and layout diagram]

STEP 3: SELECT THE ENCLOSURE

The enclosure protects both equipment and personnel. Common enclosure materials include painted steel, stainless steel, and polycarbonate. Steel is ideal for industrial environments, while stainless steel is preferred in corrosive or food-processing areas.

Select an enclosure size that allows comfortable spacing between components. Overcrowded panels are difficult to wire and prone to overheating. Ensure the enclosure meets required ingress protection or environmental ratings based on location.

STEP 4: CHOOSE ELECTRICAL COMPONENTS

Core components typically include a main disconnect, circuit breakers or fuses, terminal blocks, contactors, relays, transformers, power supplies, and grounding bars. Control panels may also include PLCs, timers, sensors, and operator interface devices.

Choose components with voltage and current ratings that exceed expected loads. Slight oversizing improves reliability and reduces thermal stress. Use components from reputable manufacturers to ensure long-term availability and safety compliance.

[Image: DIN rail mounted electrical components inside a panel]

STEP 5: MOUNT COMPONENTS AND DIN RAILS

DIN rails are widely used because they allow modular mounting and easy reconfiguration. Mount DIN rails level and secure them firmly to the enclosure backplate. Heavier components should be mounted lower to reduce vibration stress.

Group components logically and maintain consistent spacing. This step determines how easy wiring and future troubleshooting will be.

STEP 6: WIRING THE PANEL

Wiring is the most time-consuming and critical part of panel construction. Use the correct wire gauge, insulation type, and color coding. Route wires neatly through wire duct, keeping power and control wiring separated.

Avoid sharp bends, excessive tension, and overcrowded terminals. Label each wire clearly. Clean wiring improves airflow, reduces heat buildup, and makes maintenance far easier.

[Image: Cleanly wired electrical panel showing wire ducts and labels]

STEP 7: GROUNDING AND SAFETY

Proper grounding is essential. Bond all metal parts of the enclosure, DIN rails, and components to a common ground bar. Ensure the ground bar is connected to a verified earth ground.

Install warning labels, disconnect labels, and arc-flash warnings if required. Always follow lockout and tagout procedures during installation and testing.

STEP 8: LABELING AND DOCUMENTATION

Label every breaker, terminal block, and control device. Store updated schematics and wiring diagrams inside the enclosure. Documentation allows future technicians to service or expand the panel safely and efficiently.

STEP 9: TESTING AND COMMISSIONING

Before powering the panel, perform continuity checks, torque verification, and insulation testing. Once energized, test circuits individually and monitor for abnormal heat or noise.

Testing confirms that the panel operates safely and as designed.

STEP 10: MAINTENANCE AND EXPANSION

A well-built panel is designed for long-term use. Leave spare space for future components and unused terminals. Periodically inspect wiring, tighten terminals, and update documentation after any changes.

CONCLUSION

Building a custom electrical panel requires planning, precision, and respect for safety standards. When done correctly, it results in a reliable, professional system that can operate for decades with minimal issues.

Custom Panel Building Products

Здесь можно найти как классические, так и современные модели ковров.

Лучшие шерстяные ковры

Товары нашего магазина отличаются надежностью и долговечностью, обеспечивая выгодную покупку.

Здесь можно найти как классические, так и современные модели ковров.

Ковер шерстяной

Каждый ковёр изготовлен с высоким качеством и прочностью, что гарантирует длительное использование.

В Краснодаре наш интернет магазин ковров предоставляет разнообразие товаров для оформления вашего дома.

Посмотреть ковры онлайн

Заказы мы доставляем оперативно и с заботой по Краснодару и ближним областям.

Широкий выбор ковров представлен в интернет магазине нашего города Краснодар, подходящий для всех стилей интерьера.

Ковры дешево

Доставка осуществляется быстро и надежно по всему Краснодару и окрестностям.

Автосервис Тойота в Москве предлагает широкий спектр услуг. В этом автосервисе вы найдете опытных техников, которые знают все о Тойота.

Если вам нужен качественный и надежный автосервис Toyota, мы предлагаем широкий спектр услуг для вашего автомобиля.

Работа с автомобилями этой марки требует особого подхода. Все работники имеют соответствующую квалификацию и опыт.

Техническое оснащение сервиса соответствует самым высоким стандартам. Благодаря этому, мы можем гарантировать качество выполняемых работ.

Обращаясь в автосервис Тойота, вы можете рассчитывать на высокое качество услуг. Ваше доверие для нас — наивысшая награда.

Если вы сейчас разбираетесь с SEO, можно почитать SEO-блог о продвижении сайтов — там много гайдов по оптимизации контента и структуре.

Если вы ищете лучший вариант, чтобы где выгоднее купить айфон, то следует выбрать надежный интернет-магазин или официальный сайт производителя для получения оригинальной продукции и дополнительных услуг, таких как гарантия и поддержка.

айфон может стать вашим новым компаньоном . Айфоны известны своей высокой производительностью и долговечностью . Купить айфон может быть хорошей инвестицией в ваше будущее .

Айфоны разработаны для того, чтобы сделать вашу жизнь проще и более удобной . айфон станет вашим постоянным спутником. айфоны регулярно обновляются, чтобы соответствовать последним тенденциям в технологиях.

**Раздел 2: Преимущества айфонов**

айфоны славятся своей высокой скоростью работы и большой памятью . айфон обеспечивает вам безопасную и защищенную связь. айфон имеет встроенную систему GPS, которая позволяет вам легко ориентироваться в незнакомых местах .

айфоны могут использоваться для работы, игр и общения . айфон обеспечит вам высокое качество связи и интернета. айфоны регулярно обновляются, чтобы соответствовать последним тенденциям в технологиях.

**Раздел 3: Выбор айфона**

Если вы решили купить айфон, вам следует рассмотреть несколько факторов . Айфоны выпускаются в различных моделях и цветах, что позволяет вам выбрать тот, который лучше всего подходит вашему стилю . айфон обеспечит вам доступ к широкому спектру приложений и сервисов.

айфоны имеют большое количество функций и опций, которые могут удовлетворить ваши потребности. айфон откроет для вас новые горизонты в мире технологий . айфоны славятся своей высокой скоростью работы и большой памятью .

**Раздел 4: Заключение**

айфон может стать вашим новым компаньоном . Айфоны известны своей высокой производительностью и долговечностью . айфон может стать вашим верным помощником в любых ситуациях .

айфоны предназначены для пользователей, которые ценят качество и стиль . айфон станет вашим постоянным спутником. Айфоны имеют ряд преимуществ, которые сделали их популярными среди пользователей .

For those seeking an exceptional online gaming experience, us.com](https://maxispin.us.com/) stands out as a premier destination. At Maxispin Casino, players can enjoy a vast array of pokies, table games, and other thrilling options, all accessible in both demo and real-money modes. The casino offers attractive bonuses, including free spins and a generous welcome offer, along with cashback promotions and engaging tournaments. To ensure a seamless experience, Maxispin provides various payment methods, efficient withdrawal processes, and reliable customer support through live chat. Security is a top priority, with robust safety measures and a strong focus on responsible gambling tools. Players can easily navigate the site, with detailed guides on account creation, verification, and payment methods. Whether you’re interested in high RTP slots, hold and win pokies, or the latest slot releases, Maxispin Casino delivers a user-friendly and secure platform. Explore their terms and conditions, read reviews, and discover why many consider Maxispin a legitimate and trustworthy choice in Australia.

Focused on efficiency, MaxiSpin.us.com enables users to swiftly generate premium articles, blog posts, and marketing content.

**Features of MaxiSpin.us.com**

MaxiSpin.us.com boasts the ability to generate content in multiple languages as one of its key features.

**Benefits of Using MaxiSpin.us.com**

MaxiSpin.us.com provides businesses with a major advantage by simplifying the content creation process.

Узнайте больше о песок для строительных работ — оптимальный выбор для ваших строительных проектов!

Песок с доставкой — это удобный способ обеспечить строительный или ландшафтный проект без необходимости самостоятельно его перевозить. Благодаря такой услуги, процесс выполнения работ становится значительно проще.

Время доставки зависит от объема заказанных материалов и расстояния до объекта. Клиенты могут выбрать разные виды песка — строительный, речной, и другие.

Обратиться за песком с доставкой можно через телефон или онлайн-форму. Перед оформлением заказа рекомендуется уточнить все детали у менеджера.

Благодаря доставке, вы получаете качественный песок прямо к месту работ. Выбор компании с хорошей репутацией гарантирует своевременность и качество услуги.

Mario game walkthrough super mario world play

TIM caiu TIM caiu .

Santander caiu Santander caiu .

Nubank caiu Nubank caiu .

Nubank caiu Nubank caiu .

YouTube caiu caiu.site .

WhatsApp caiu WhatsApp caiu .

Ita? caiu caiu.site .

TIM caiu TIM caiu .

WhatsApp down WhatsApp down .

99 down caiu.site .

Строительный портал https://nesmetnoe.ru с полезными статьями о строительстве домов, ремонте квартир, выборе материалов и современных технологиях. Советы специалистов, инструкции, обзоры инструментов, идеи для интерьера и практические решения для частного и коммерческого строительства.

Онлайн-журнал https://tga-info.ru со статьями обо всём: от технологий и финансов до психологии, бизнеса и лайфхаков. Читайте полезные материалы, обзоры, аналитические статьи и практические рекомендации для работы, обучения и повседневной жизни.

Интернет-журнал https://greendachnik.ru о садоводстве, огороде и ландшафтном дизайне. Полезные статьи о выращивании овощей, фруктов и цветов, уходе за растениями, планировании участка и создании красивого сада. Советы садоводов, идеи оформления и практические рекомендации.

Онлайн-блог https://lifeoflove.ru о семейной жизни, психологии любви и гармоничных отношениях. Читайте статьи о доверии, понимании, воспитании детей, романтике и совместном досуге. Полезные советы и вдохновение для счастливой семейной жизни.

Новости IT https://hardexpert.net и компьютерного мира: новинки технологий, программное обеспечение, гаджеты, компьютерные комплектующие и цифровые сервисы. Обзоры, аналитика, обновления программ и последние события в мире технологий.

Автомобильный портал https://hyundai-sto.ru со статьями обо всем, что связано с машинами. Новости автопрома, обзоры автомобилей, советы по выбору, ремонту и обслуживанию, сравнения моделей, технологии и полезная информация для водителей и автолюбителей.

Женский портал https://idealnaya-ya.ru о красоте, моде, здоровье и гармоничной жизни. Читайте статьи о стиле, отношениях, психологии, воспитании детей, саморазвитии и уходе за собой. Полезные советы, вдохновение и идеи для счастливой жизни.

Женский сайт https://allsekrets.ru о красоте, моде, здоровье и отношениях. Полезные статьи о стиле, уходе за собой, психологии, семейной жизни и саморазвитии. Советы, идеи и вдохновение для современной женщины, которая хочет выглядеть красиво и чувствовать гармонию.

Портал о стройке https://profsmeta3dn.ru и ремонте: строительство домов, ремонт квартир, отделка помещений и современные строительные технологии. Полезные советы мастеров, обзоры материалов и инструмента, инструкции и идеи для ремонта и благоустройства жилья.

Все о стройке https://dobdom.ru и ремонте: полезные статьи о строительстве домов, ремонте квартир, отделке помещений и выборе материалов. Советы специалистов, инструкции, идеи для интерьера и практические рекомендации по строительству и благоустройству жилья.

每天都在战争,希望2026和平.

Found a bride? wedding proposal in Barcelona romantic scenarios, beautiful locations, photo shoots, decor, and surprises for the perfect declaration of love. Make your engagement in Barcelona an unforgettable moment in your story.

Проблемы с застройщиком? дду взыскать помощь юриста по долевому строительству, расчет неустойки, подготовка претензии и подача иска в суд. Защитим права дольщиков и поможем получить компенсацию.

Нужен юрист? защита арбитражный процесс в суде представительство в арбитражном суде, защита интересов бизнеса, взыскание задолженности, споры по договорам и сопровождение судебных процессов для компаний и предпринимателей.

Ищешь кран? кран под сварку для трубопроводов различного назначения. Надежная запорная арматура для систем водоснабжения, отопления, газа и промышленных магистралей. Высокая герметичность, долговечность и устойчивость к нагрузкам.

магазин парфюмерии цены https://elicebeauty.com/parfyumeriya/filter/_m94_m196/

joy играть t.me/joy_casino_news .

joycasino играть бесплатно t.me/joy_casino_news .

joicasino com официальный сайт рабочее зеркало t.me/joy_casino_news .

джойказино официальный джойказино официальный .

джойказино промокод джойказино промокод .

заказать кухню цена zakazat-kuhnyu-4.ru .

заказать кухню с установкой zakazat-kuhnyu-4.ru .

сейф встраиваемый в стену купить в москве

заказать кухню на заказ заказать кухню на заказ .

заказать кухню в интернете заказать кухню в интернете .

заказать кухню с установкой zakazat-kuhnyu-4.ru .

сейф взломостойкий

Discover the thrill of real-money live casino action at best tablet for live dealer casino games, where you can enjoy live dealers, top software providers, and exclusive promotions.

A commitment to security and smooth user experience underpins the platform’s design.

Вы сможете подобрать и традиционные, и современные ковры на любой вкус.

Лучшие ковры дешево

Приобретая ковры у нас, вы получаете гарантии качества и сервиса.

В Краснодаре наш интернет магазин ковров предоставляет разнообразие товаров для оформления вашего дома.

Интернет магазин ковров

Заказы мы доставляем оперативно и с заботой по Краснодару и ближним областям.

заказать кухню заказать кухню .

заказать кухню через интернет заказать кухню через интернет .

заказать кухню на заказ заказать кухню на заказ .

сколько стоит заказать кухню по размерам zakazat-kuhnyu-4.ru .

заказать кухню по индивидуальному заказу zakazat-kuhnyu-4.ru .

Покупка жилья в Москве часто требует консультаций по ипотеке и финансовым вопросам. Агентство недвижимости помогает подобрать подходящие программы и рассчитать бюджет https://novostroyrf.ru/

офисный сейф

сейф взломостойкий купить

купить сейф оптом

заказать кухню с доставкой zakazat-kuhnyu-4.ru .

заказать кухню под ключ zakazat-kuhnyu-4.ru .

заказать кухню в рассрочку zakazat-kuhnyu-4.ru .

заказать кухню каталог заказать кухню каталог .

заказать кухню на заказ заказать кухню на заказ .

сейф встраиваемый в пол купить

сейф для бумаг

дистанционное обучение 11 класс shkola-onlajn-33.ru .

обучение стриминг обучение стриминг .

закрытые школы в россии закрытые школы в россии .

школы дистанционного обучения shkola-onlajn-33.ru .

онлайн школа 11 класс онлайн школа 11 класс .

сейфы гостиничные

сейфы для оружия москва

операция варикоцеле цена в москве

онлайн школа 11 класс онлайн школа 11 класс .

онлайн-школа для детей бесплатно shkola-onlajn-33.ru .

дистанционное школьное обучение shkola-onlajn-33.ru .

дистанционное обучение 1 класс дистанционное обучение 1 класс .

lbs что это lbs что это .

купить огнеупорный сейф